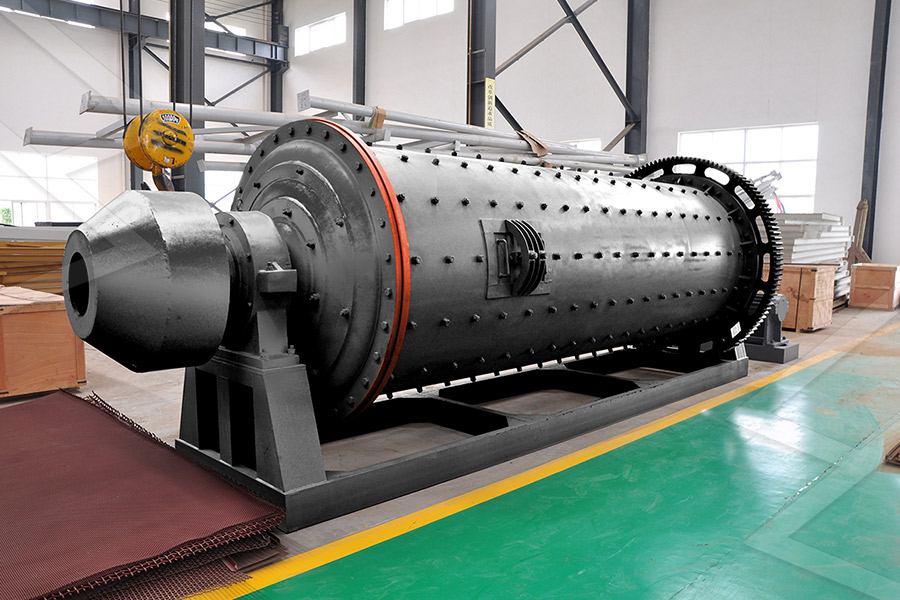

High Quality And Long Life Energy Saving Mine New Design Ball Mill

THE REVOLUTION IN ULTRAFINE GRINDING RETSCH

The Emax is an entirely new ball mill designed for high energy grinding The maximum speed of 2000 rpm, so far unrivaled in a ball mill, and the innovative jar design produce The ball mill utilizes premium components, including Siemens motors, SEW gear reducers, SKF bearings, and ABB electrical parts, ensuring high efficiency and energy savings With over 20,000 hours of bearing life, it Ball Mills Manufacturer JXSC2023年12月28日 — The energysaving and high production of the ball mill is a systematic project Each link is interconnected and restricts each other The best energy saving and high production results can be achieved only Factors Affect The Output and Quality of Ball 2024年8月23日 — Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 — Ball mill efficiency directly affects the cost of mineral processing Grinding media play a vital role in enhancing the efficiency of a ball mill through their direct effect Mill processing capacity is enlarged on the premise of stable concentrate particle size to increase grinding efficiency and concentrate production, continuously perfect production Intelligent Control and Energy Conservation of Ball Mill2020年9月1日 — Based on the latest achievements in the literature, this review will: (a) delineate the principles and fundamentals for biochar ball milling; (b) evaluate the Ball milling as a mechanochemical technology for fabrication 2024年8月22日 — Highenergy ball milling is a complicated process employed in solid reactions for obtaining nanostructured materials, in powder form, with an average particle Modelling of the HighEnergy Ball Milling Process

What is a Ball Mill Explained: InDepth Guide

2024年4月28日 — Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead 2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within a very short process time The high energy input is a High Energy Ball Mills Instead of Planetary Ball 2023年4月23日 — ciency include mill design, liner design, mill speed, charge ratio, and grinding media properties The authors also indi cated that circuit efficiency is determined by how well the power applied (PDF) Grinding Media in Ball MillsA Review ResearchGate

Ball Mill JXSC Mineral

6 天之前 — Ball Mill Working Principle High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, 2019年11月26日 — The feed of the ball mill contains grinding balls In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possibleWhat’s the Difference Between SAG Mill and Ball Mill2021年10月27日 — Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball Mill,Ball 2024年8月23日 — Energysaving ball mills and cement ball mills are both commonly used grinding equipment in the industrial field, but they differ in design purpose, application field, and technical characteristics 1 Design Energysaving ball mill: designed to reduce energy consumption and improve grinding efficiency Energysaving ball mills can be used for Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral

Exploring Ball Mill Diagram: A Comprehensive Guide JXSC

2024年4月28日 — Through careful assessment of the mill’s working principles, construction, operation, and efficiency determinants, operators and engineers can make wellinformed decisions to ensure the maximum grinding efficiency and the output of highquality products in many fields, such as mining, mineral processing, ceramics, and paints2024年9月12日 — High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semi Grinding Mills Mineral Processing Equipment2024年8月22日 — this work, the highenergy planetary ball mill process is modeled using the soft ware Automated Dynamic Analysis of Mechanical System MSC Adams[22] Figure 2 illustrates a schematic of a high Modelling of the HighEnergy Ball Milling Process2024年8月8日 — In mining, it's used for ore processing, enabling the extraction of valuable minerals The pharmaceutical industry relies on it to create uniform particle sizes, enhancing drug solubility and absorption Ball Mill Success: A StepbyStep Guide to

High‐Energy Ball Milling as a General Tool for Nanomaterials Synthesis

2015年3月23日 — ENEA – Italian National Agency for New Technologies, Energy and Sustainable Economic Development, Technical Unit of Materials – Materials Chemistry and Technology Lab, Research Centre Casaccia, via Anguillarese, 301, 00123, Rome, Italy This chapter reports some fundamental thermodynamic and kinetic aspects of the high High geometric precision: The molding process of mill balls adopts highprecision molding processes such as compression molding and injection molding, which can control the size, density, and shape of the balls to ensure their geometric accuracy and consistency, thereby improving the grinding efficiency and product quality of the ball mill Ball Mill Balls Manufacturing Of High Quality Ball Mill BallFigure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationThe Selection and Design of Mill Liners MillTraj2006年1月1日 — The relining time also reduced by 375% with the new liners Powell et al, 2006; Rajamani, 2006;Yahyaei et al, 2009;MalekiMoghaddam et al, 2013;MalekiMoghaddam et al, 2015;Cleary and Owen (PDF) Selection and design of mill liners ResearchGate

High Energy Ball Milling Stirred Ball Mill Stirred Media Mill

In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the differences between the types of mills are quite distinct And, depending on your application, you may find that one type of high energy ball milling is moreEnergysaving ball mill is a new kind of ball mill grinder developed by us for solving the shortcomings of ordinary ball mill, such as high energy consumption, low output, and low finenessIt is a highefficiency grinder in the ball mill series, which is widely favored by users In the production process, the energysaving ball mill reduces the energy consumption by High Efficiency Energy Saving Ball Mill For Sale AGICO Ball Mill High Energy Ball Mill E max Sample volume up to 2 x 45 ml ; Final fineness*: 008 µm; Highly effective size reduction mechanism ; Water cooling permits continuous operation; Product details; Nanoscale Grinding Mixer Mill MM 500 Nano Material feed size*: = 10 mm Final fineness*: ~ 01 µm Retsch : Products : Milling : High Energy Ball Mills2023年10月20日 — The basic components and structure of a ball mill play a crucial role in its operation and performance Understanding these elements is essential for effectively operating the equipment 1 Cylindrical Shell Comprehensive Guide on Operating a Ball Mill

EnergyEfficient Technologies in Cement

2016年10月5日 — In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over 2024年6月20日 — In the face of global climate change, there is a pressing and significant need to find lowcarbon solutions for China’s construction industry This research focuses on green public buildings in Dalian, a Green Building Performance Analysis and Energy 2024年8月20日 — Carbon fiber reinforced polymer (CFRP) composites have very high specific properties, which is why they are used in the aerospace, wind power, and sports sectors However, the high consumption of CFRP compounds leads to a high volume of waste, and it is necessary to formulate mechanical recycling strategies for these Technologies for Mechanical Recycling of Carbon Fiber 2022年1月19日 — Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break the liners Typically, a ball mill lining has a more rounded profile, often like a sine wave, and the size of the waves is selected based on the size of grinding media usedEBOOK Three factors that determine the wear life and

Ball Mill (Ball Mills Explained) saVRee saVRee

Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to 2023年11月1日 — 1 Introduction Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is Energy conservation and consumption reduction in grinding [Introduction] : Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing [Capacity] : Up to 160t/h [Improvement] : Cylindrical energysaving grid ball mill is lined with the grooved ring plate which increases the contact surface of ball and ore, strengthens the grinding effect, and has the ability to improve the ore with lower energy Energy Saving Ball Mill, Ball Mill Design, Ball Milling Process2017年8月24日 — Alloying of elemental blends achieved through highenergy ball milling (HEBM) is referred to as mechanical alloying (MA), which is a solidstate powder processing technique involving the repeated deformation, fracture and welding of powder particles [1,2,3,4]This technique was originally developed to produce oxidedispersion HighEnergy Ball Milling Parameters in Production of

Ball Mill an overview ScienceDirect Topics

The history and necessity of mechanical alloying M Sherif ElEskandarany, in Mechanical Alloying (Second Edition), 2015 2515 Planetary ball mills The Planetary ball mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Figure 11 In this type of mill, the milling media have 2024年8月22日 — Ball mill is the key equipment for grinding materials crushing It is suitable for grinding various ores and other materials It is widely used in mineral processing, building materials and chemical industry The equipment has the characteristics of stable operation, reliable operation, large production capacity and long service lifeEnergy Saving Small Capacity Lead Gold Zinc Aluminum Powder Ball Mill 2017年2月13日 — Grinding (Rod) or (Ball) Mill TYPE D Has single weld, triple flanged, construction which means the shell is furnished in two sections, flanged and bolted in the center All flanges are double welded as well as Ball Mills 911Metallurgist2024年9月20日 — Ball Mill (QMJ), Find Details and Price about Ball Mill Energy Saving Ball Mill from Ball Mill (QMJ) Henan Kingstate Heavy Industry Machinery Co, Ltd national large bridge, subbottom tunnel, land tunnel and newtype high building material usage AAC blocks making machines are applicable to make building material, according to the Ball Mill (QMJ) Ball Mill and Energy Saving Ball Mill Made

Energy Efficient Ball Mill Circuit – Equipment Sizing Considerations

2013年7月15日 — The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of theEnergysaving Ball Mill Processing capacity up to 160t/h; long service life and less faults; A small proportion of rubber lining part, energysaving and costreducing; More than 2,000 mine design and research, equipment supply projects, more than 500 mining industry chain services (EPCM+O) projects in more than 100 countries and Xinhai Mining Mineral Processing, Equipment Manufacturers, Ball 2024年5月15日 — Shanghai Tower has become a new landmark of Shanghai In the current trend advocating green building and energy efficiency, considerations of wind loads and thermal characteristics of the perimeter structure of Shanghai Tower are crucial This paper conducts comparative simulation studies on the wind environment of Shanghai Tower Analysis and Reflection on the Green, LowCarbon, and EnergySaving BM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonateMixer/Mill – highenergy ball mills, mechanical alloying,

Intelligent optimal control system for ball mill grinding

2017年8月27日 — The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin The schematic diagram of this process is shown in Fig 1 Fig 1 Schematic diagram of ball mill grinding process The variables of this process shown in Fig 1 are explained as follows: W2024年6月19日 — Rechargeable lithium/sulfur (Li/S) batteries have long been considered attractive beyond lithiumion options due to their high theoretical energy density (up to 2,500 Wh kg −1)Recently, in attempts to limit the reliance on unsustainable transitionmetalbased cathode materials while maintaining high cell energy density, sulfur, as a lowcost and Realizing highenergy and longlife Li/SPAN batteries2024年4月28日 — Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead What is a Ball Mill Explained: InDepth Guide2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral

High Energy Ball Mills Instead of Planetary Ball

The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within a very short process time The high energy input is a 2023年4月23日 — ciency include mill design, liner design, mill speed, charge ratio, and grinding media properties The authors also indi cated that circuit efficiency is determined by how well the power applied (PDF) Grinding Media in Ball MillsA Review ResearchGate6 天之前 — Ball Mill Working Principle High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, Ball Mill JXSC Mineral2019年11月26日 — The feed of the ball mill contains grinding balls In order to effectively reduce the direct impact of materials on the ball mill feed bushing and improve the service life of the ball mill feed bushing, the feeding point of the groove in the feeding part of the ball mill must be as close to the side of the mill barrel as possibleWhat’s the Difference Between SAG Mill and Ball Mill

Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball Mill,Ball

2021年10月27日 — Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui 2024年8月23日 — Energysaving ball mills and cement ball mills are both commonly used grinding equipment in the industrial field, but they differ in design purpose, application field, and technical characteristics 1 Design Energysaving ball mill: designed to reduce energy consumption and improve grinding efficiency Energysaving ball mills can be used for Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral2024年4月28日 — Through careful assessment of the mill’s working principles, construction, operation, and efficiency determinants, operators and engineers can make wellinformed decisions to ensure the maximum grinding efficiency and the output of highquality products in many fields, such as mining, mineral processing, ceramics, and paintsExploring Ball Mill Diagram: A Comprehensive Guide JXSC