Ball Mill Manufacturing Procedures Steel Ball Manufacturing Process In Factor

Grinding in Ball Mills: Modeling and Process Control

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media 2024年7月25日 — In the steel ball production process, the first step is stamping, a key technique for giving the ball its rough shape Stamping involves processing steel wire or How are steel balls produced? UmbraGroupBall milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel Ball Milling an overview ScienceDirect Topics2024年9月22日 — Ball milling is a mechanical process that involves the rotation of a drum containing grinding media, typically steel balls, at a high speed The materials to be Exploring ball milling theory: A comprehensive guide

New industrial technology for producing mill balls in a

1999年8月30日 — The fields of application of grinding steel balls are in ore processing and the cement industry (material grinding in ball mills); largesize rolling bearings, etc In 2019年11月4日 — The steel ball manufacturing process can be roughly divided into three types: casting, rolling and forging Steel Ball Manufacturing Process Comparison Casting Steel Ball Manufacturing ProcessSteel Ball made in different process methods 2021年2月19日 — Taguchibased experimental design technique provides a systematic and efficient mathematical approach to understand complex process of ball mill process Comparative Study on Improving the Ball Mill Process 2023年11月17日 — Helical rolling (HR) with high temperature is an efficient forming process to produce bearing steel balls with diameter more than 25 mm This article discusses the Numerical and experimental investigation of helical rolling process

(PDF) Grinding in Ball Mills: Modeling and Process Control

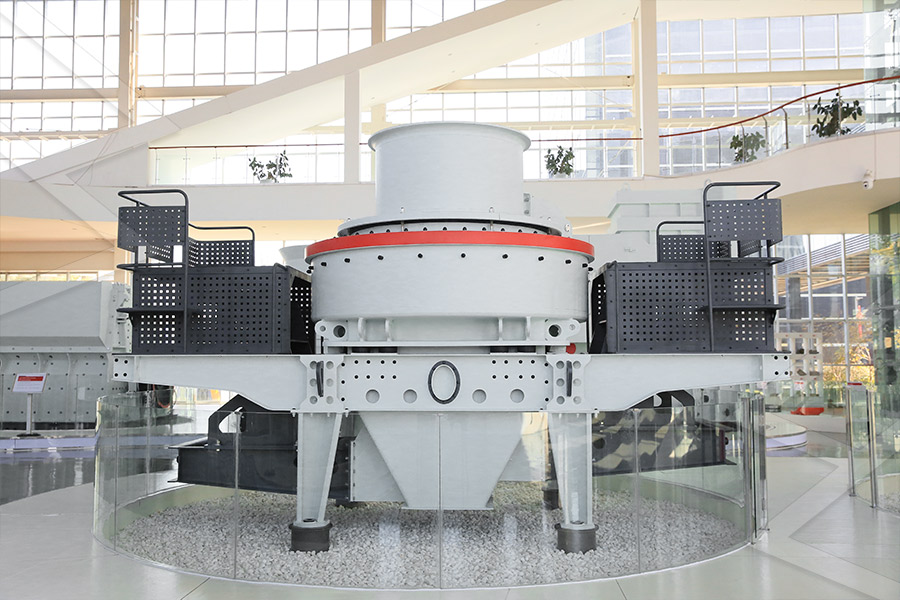

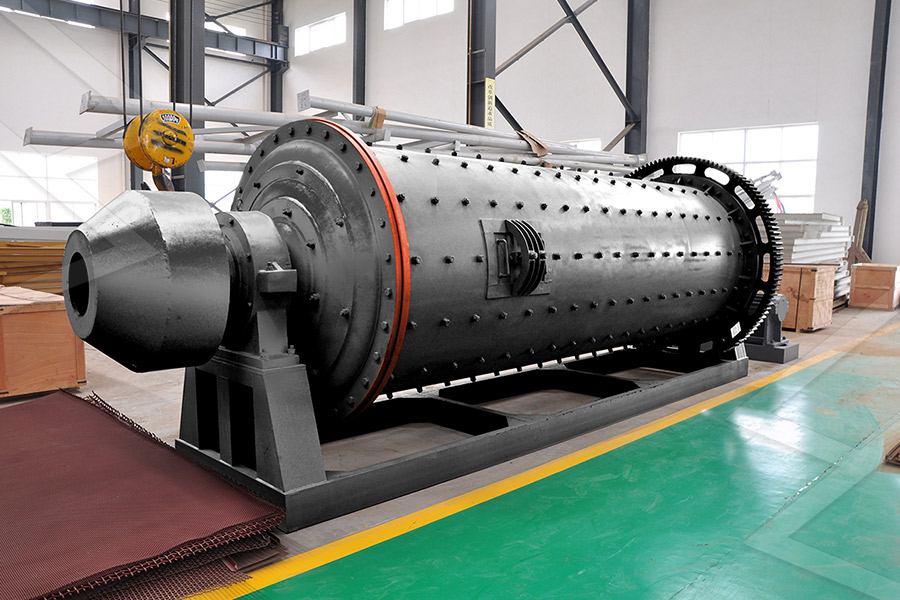

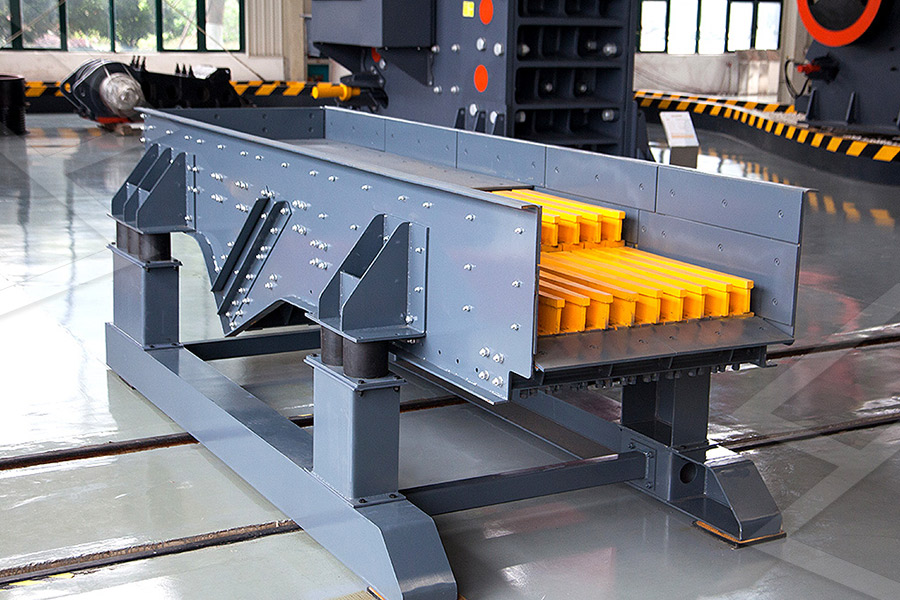

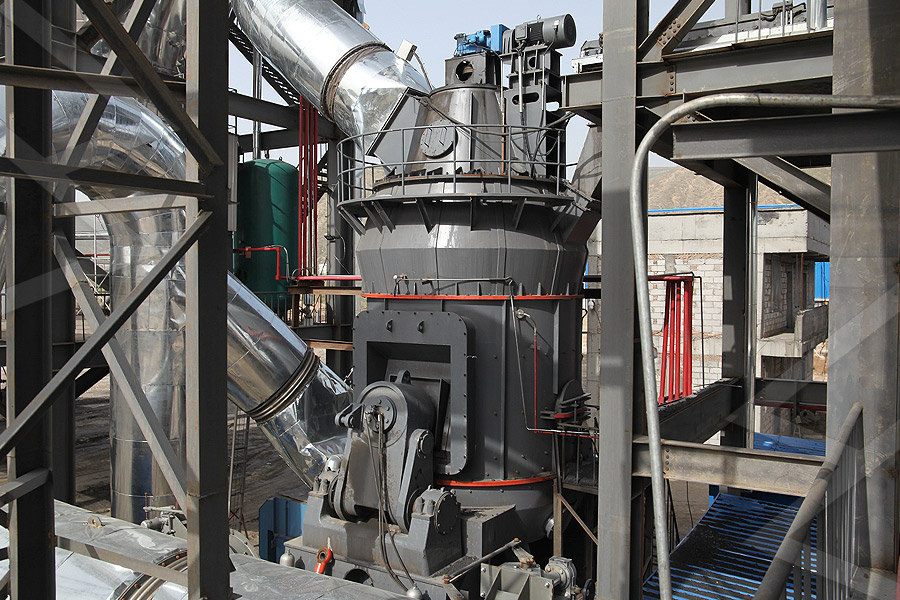

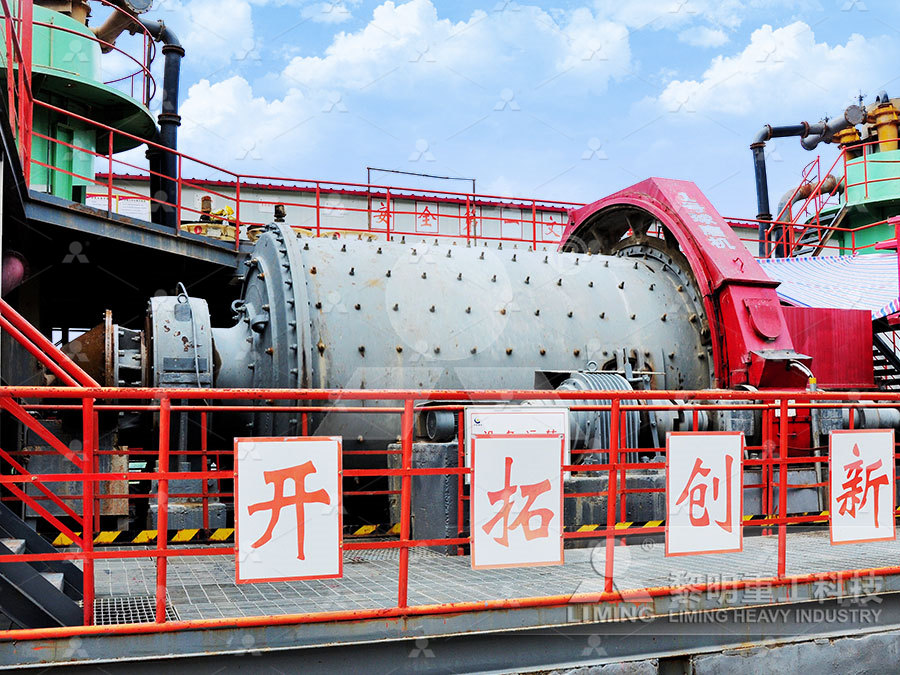

2012年6月1日 — The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball millsBall mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig 410 A–C, or flint Ball Mill an overview ScienceDirect Topics2023年7月10日 — Milling is a type of machining process that uses a rotating cutter to remove material in a controlled manner from a workpiece This subtractive manufacturing technique aims to turn the workpiece into the What is Milling: Definition, Process OperationsBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball Ball Mill (Ball Mills Explained) saVRee saVRee

Steel Ball Manufacturing Process Analysis and

2019年9月19日 — Steel ball skew rolling mill is a ball automated production equipment, suitable for the production of steel balls with various materials: carbon steel, manganese steel The rolled steel balls are widely used in 2023年11月17日 — Helical rolling (HR) with high temperature is an efficient forming process to produce bearing steel balls with diameter more than 25 mm This article discusses the advantages and disadvantages of two HR roller designing methods: single side variable lead method and double side variable lead method Finite element (FE) simulations of HR Numerical and experimental investigation of helical rolling process Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc2024年1月22日 — The primary raw material used in steel ball manufacturing is steel wire The wire is typically made from highcarbon steel or alloy steel Cutting the Wire: The steel wire is cut into shorter lengths to form individual ball blanks The length of the wire corresponds to the diameter of the steel balls being produced Heading:How steel balls are manufactured? Grinding Ball

Ball Mill Grinding Machines: Working Principle, Types, Parts

Cement Industry: Ball mills are extensively used in the cement industry for grinding raw materials, clinker, and additives to produce cement The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturing2024年4月26日 — Understanding the Manufacturing Steel Ball Process The process of manufacturing steel balls may seem straightforward at first glance, but it involves a sophisticated series of steps that are precisely executed to yield a product that meets stringent industry standards Integral to countless applications, from automotive bearings Inside Steel Ball Production: Secrets of Crafting UnveiledSteel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis Our combined experience in ball mill design and process equipment development Orbis Machinery Ball Mills Ball Mill Drive2024年8月20日 — The manufacturing process of steel ball is also a critical factor in determining its service life If there are defects on the surface or inside of the steel ball, such as shrinkage cavity, crack, transgranular and so on, not only the properties of the steel ball will be reduced, but also the steel ball will be brokenGrinding Balls: Casting and Forging based on manufacturing process

High Quality Precision Ball Steel Balls

2017年4月5日 — After the primary manufacturing process, every lot of precision steel balls undergoes multiple inprocess quality control checks A visual inspection is performed to check for defects such as rust or dirt 2017年3月28日 — Ball bearings are rolling element bearings that use balls to separate the bearing races and provide smooth, low friction motion in rotary applications Ball bearings are manufactured in hundreds of sizes, from How ball bearings are manufactured GlobalSpec2024年4月28日 — Ceramic and rubber balls are used in processes where steel balls are unsuitable for contamination, eg, in the production of ceramic raw materials and paint The lining of shell is a necessary part which is responsible for protecting the mill’s shell from the wear and tear induced by the impact and abrasion of the grinding mediaExploring Ball Mill Diagram: A Comprehensive Guide JXSC2014年10月10日 — by Modeling and Analysis of parts of ball mill by using ‘Finite Element Method’ Keywords:Parameters, ball mill, modeling and analysis I INTRODUCTION Ball mill is vital equipment used in industries for mineral dressing, ore processing, fertilizers, paint industries, food and diary, pharmaceuticals and many others In ball mills,Design and Analysis of Ball Mill For Paint Industries IJSRD

.jpg)

The 7 Steps Behind the Ball Manufacturing Process

2024年9月24日 — The manufacture of precision balls is a combination of an exacting science, hands on experience, and the most modern facilities for efficient ball production Only the finest grades of ball wire are used, selected and inspected to Hartford’s high standards before the manufacturing process starts2024年2月20日 — However, if ball mills are able to accommodate the requisite amounts of material for processing, laboratory mills are occasionally deployed in smallscale battery production pilot plants In commercialscale production processes, agitator bead mills, vibrating bead mills, or continuous horizontal axis bead mills are the most commonplace How Ball Mills Contribute to Battery Technology AZoM2024年5月27日 — The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills have various designs and functions, ranging from laboratoryscale versions to large industrial modelsBall Mills in the Mineral Processing Industry MechProTech2024年2月10日 — The manufacturing processes involved in ball fabrication play a crucial role in producing highquality balls that meet the requirements of various industries From forging to heat treatment, each process contributes to the strength, durability, and performance of the final productManufacturing Processes: The Heart of Ball Fabrication

Modelling Power Consumption in BallEnd Milling Operations

2011年5月10日 — Power consumption is a factor of increasing interest in manufacturing due to its obvious impact on production costs and the environment The aim of this work is to analyze the influence of process parameters on power consumption in highspeed ballend milling operations carried out on AISI H13 steel2024年1月13日 — Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate2018年6月22日 — Grinding steel ball is highly popular because its main applicants are gold, copper, Fe ore, and polymetallic The manufacturing process of grinding steel ball is forged and cast Grinding steel ball is actually produced from the wide range of alloysThe manufacturing process of grinding steel balls2024年7月12日 — Whether you need a standard size or a custombuilt ball mill to meet your specific needs, our team is here to assist Contact us online or call (606) 7985724 to learn more about how our ball mills can improve your production processes Let us help you achieve precise material grinding with our reliable milling solutionsWalking Through the Ball Milling Process Economy Ball Mill

Ball Bearing Manufacturing Process

2023年5月30日 — The manufacturing process of ball bearings typically involves several steps Let’s break down the process step by step: Material Selection Wire Drawing Heading Cold Heading Heat Treatment Grinding Lapping Assembly and Packing It’s important to note that the specific ball bearing manufacturing process can vary depending on factors such 2023年4月23日 — pending on the process parameters which are fill rate, mill spe ed, ball diameter, ball shape and grinding time [41] In the ball mill, friction is formed due to the difference between surfa ces (PDF) Grinding Media in Ball MillsA Review ResearchGate1999年8月30日 — The fields of application of grinding steel balls are in ore processing and the cement industry (material grinding in ball mills); largesize rolling bearings, etc In mass machine production, for the manufacturing of axisymmetric forgings, cylindrical billets can be effectively replaced by ballsNew industrial technology for producing mill balls in a 2023年7月18日 — The ball valve manufacturing process consists of several different steps or stages As we have seen, it can also involve forging or casting metal Each manufacturing process has its benefits and disadvantages, and the manufacturer may use either Here, we’ll focus on the forging process This ball valve manufacturing method is the most Ball Valve Manufacturing Process: How are Ball Valves Made?

Where Are Golf Balls Made: Exploring the Manufacturing Process

2024年9月3日 — While the United States has several major hubs for golf ball production, the majority of golf balls sold globally are made in China China has a huge textile industry, which has helped it become a hub for golf ball production Callaway has a manufacturing facility in Suzhou, China, which produces a significant portion of the company’s golf balls2024年9月22日 — It works on the principle of impact and friction between rotating balls and the powder materials The ball mill consists of a rotating drum and a hollow cylinder filled with grinding media, typically small metal balls Working Principle of a Ball Mill The working principle of a ball mill is based on the rotation of the drum, which causes the Understanding the mechanism: How does a ball mill work?2019年10月30日 — The process combines the characteristics of forging and rolling steel balls, and takes CNC die forging hammer or electric screw press as the core steel ball making machine, matching bar cutting machine, forging manipulator, rounding machine and other equipment to achieve fullautomatic and efficient production of forged steel ballsHow to Choose Steel Ball Manufacturing Process and 2023年2月15日 — High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% 10% 4 when the moisture is greater than 5%, the ball mill will be 17 Signs of Problems with Ball Mills: Quickly

.jpg)

Ball Mill Balls Manufacturing Of High Quality

High wear resistance: The manufacturing materials of mill balls are usually high hardness and high strength materials, such as steel, ceramics, hard alloys, etc, which have high wear resistance This enables the mill balls 2020年10月29日 — Quality control is critical in the manufacturing process of precision balls Learn more about best practices for precision ball manufacturing for best quality Tel: 8605713602 The Precision Ball Manufacturing Process2023年11月23日 — Boosting productivity and quality in mining operations is a priority for many companies, and one of the key elements in achieving this goal is the use of highquality grinding media, specifically steel grinding ballsThese balls play a crucial role in the grinding of raw materials in cement plants, energy generating companies, ore mining, Steel Grinding balls an optimal choice for mining in ball mills2007年12月1日 — A dynamical design space for the batch milling process of a hazelnutandcocoabased paste in a stirred ball mill was obtained through functional data analysis (FDA) combined with design of Optimization of processing parameters of a ball mill refiner

.jpg)

Demystifying the Ball Milling Process: Expert Insights JXSC

2024年7月2日 — Ball mills are highly efficient for fine and ultrafine grinding, and they are versatile for various materials However, they have high energy consumption and require regular maintenance to ensure optimal performance Rod Mill: Similar to a ball mill, but uses long steel rods as the grinding media The rods grind the ore by tumbling within the A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentBall mill, Ball grinding mill All industrial manufacturers2012年6月1日 — An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented Abstract The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding Grinding in Ball Mills: Modeling and Process Control2016年1月1日 — Optimization of production of fat filling in a laboratory ball mill would imply the maximum agitator shaft speed and 30min milling time Sensory evaluation of the chocolate quality using the (PDF) Optimization of the ball mill processing parameters in the

The Process Control in Manufacturing: Inspection of Ball

The Process Control in Manufacturing: Inspection of Ball Bearings PRIME 2001, 1st International Seminar on: PRogress in Innovative Manufacturing Engineering EdPMLonardo, Sestri Levante (GE) Italy, June, 20th22nd, 2001, ISBN:8801, p405410 The Process Control in Manufacturing: Inspection of Ball Bearings M 2023年7月10日 — Milling is a type of machining process that uses a rotating cutter to remove material in a controlled manner from a workpiece This subtractive manufacturing technique aims to turn the workpiece into the What is Milling: Definition, Process OperationsBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball Ball Mill (Ball Mills Explained) saVRee saVRee2019年9月19日 — Steel ball skew rolling mill is a ball automated production equipment, suitable for the production of steel balls with various materials: carbon steel, manganese steel The rolled steel balls are widely used in Steel Ball Manufacturing Process Analysis and

Numerical and experimental investigation of helical rolling process

2023年11月17日 — Helical rolling (HR) with high temperature is an efficient forming process to produce bearing steel balls with diameter more than 25 mm This article discusses the advantages and disadvantages of two HR roller designing methods: single side variable lead method and double side variable lead method Finite element (FE) simulations of HR Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your Ball Mills Economy Ball Mill/JSB Industrial Solutions Inc2024年1月22日 — The primary raw material used in steel ball manufacturing is steel wire The wire is typically made from highcarbon steel or alloy steel Cutting the Wire: The steel wire is cut into shorter lengths to form individual ball blanks The length of the wire corresponds to the diameter of the steel balls being produced Heading:How steel balls are manufactured? Grinding BallCement Industry: Ball mills are extensively used in the cement industry for grinding raw materials, clinker, and additives to produce cement The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturingBall Mill Grinding Machines: Working Principle, Types, Parts

Inside Steel Ball Production: Secrets of Crafting Unveiled

2024年4月26日 — Understanding the Manufacturing Steel Ball Process The process of manufacturing steel balls may seem straightforward at first glance, but it involves a sophisticated series of steps that are precisely executed to yield a product that meets stringent industry standards Integral to countless applications, from automotive bearings Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis Our combined experience in ball mill design and process equipment development Orbis Machinery Ball Mills Ball Mill Drive