Who Manufactures Sag And Ball Mills

MCGBLSAGTS20 Version 20 SAG Balls

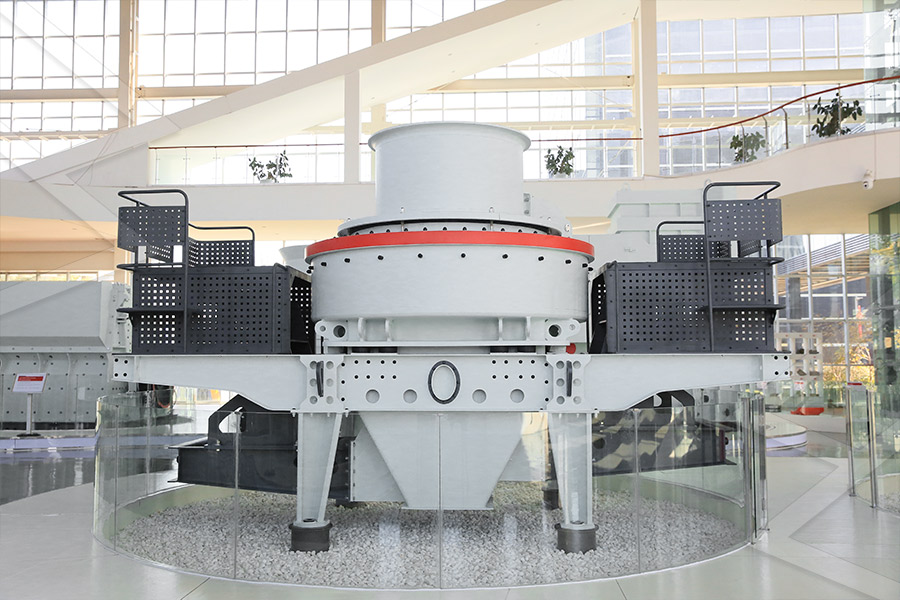

2023年9月27日 — SAG Milling Molycop manufactures balls for grinding operations (using high carbon alloy steel bars as the raw material) through special bar heating, forging and heat treatment processes, the objective of which is to obtain optimum wear and impact 球磨机(Ball Mill)、自磨机(AG Mill)、半自磨机(SAG Mill)可应用于电力、黑色金属和有色金属选矿、化工、建材等行业,它是将一定粒度的矿石或其它物料磨制成更细粒度 自磨机,半自磨机Since the early 1980s, we have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in SAG Mill Autogenous and SemiAutogenous 球磨机和 SAG(半自磨)磨机的主要区别在于它们的运行机制和研磨材料。 球磨机利用钢棒、钢球或类似介质研磨物料。 SAG 磨机则使用大块矿石和钢球进行碾磨。球磨机和 Sag 磨机有何区别?4 大关键区别说明 Kintek

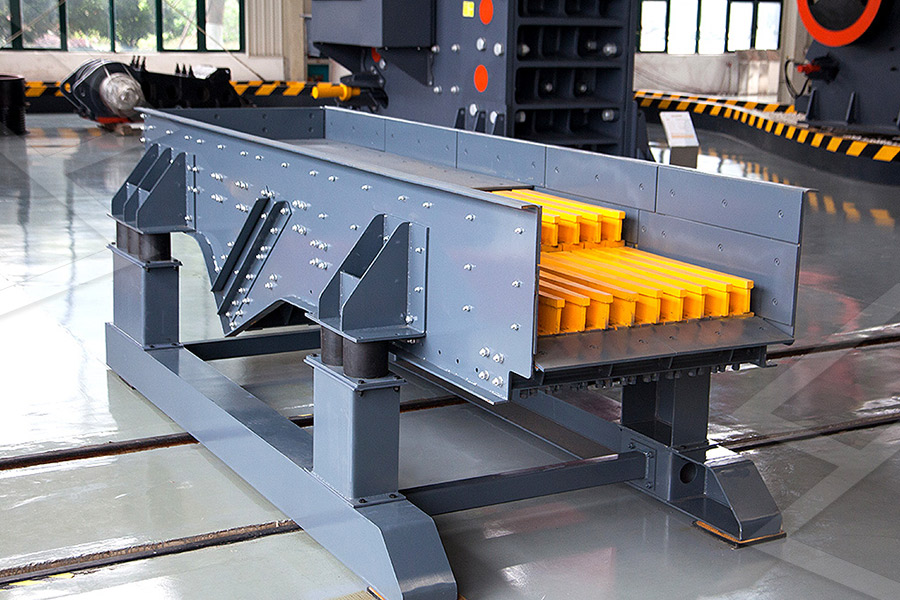

Mill Liners Bradken

Bradken is a leading engineered grinding mill solutions provider, supported by inhouse design and manufacture of highquality mill liner components to suit AG/SAG, Ball and Rod Mills By utilising the latest research and Updates have been solicited from all major mill manufacturers and most have responded A review of AG/SAG mills sold to date, and since the last SAG Conference, indicatesTop 10 countries buying AG/SAG mills Download TableOutotec has recently been awarded a contract to deliver one of the largest grinding mills in the world The contract includes the design and manufacture of a Ø 40’ x 29’ SAG mill The mill will be driven by a Outotec presents the world’s largest SAG mill2024年9月25日 — Metso calls itself a world leader in developing and manufacturing highperformance mill liners It pioneered the use of rubber linings and invented PolyMet™, SAG mills Archives International Mining

MCGBLSAGTS20 Version 20 SAG Balls

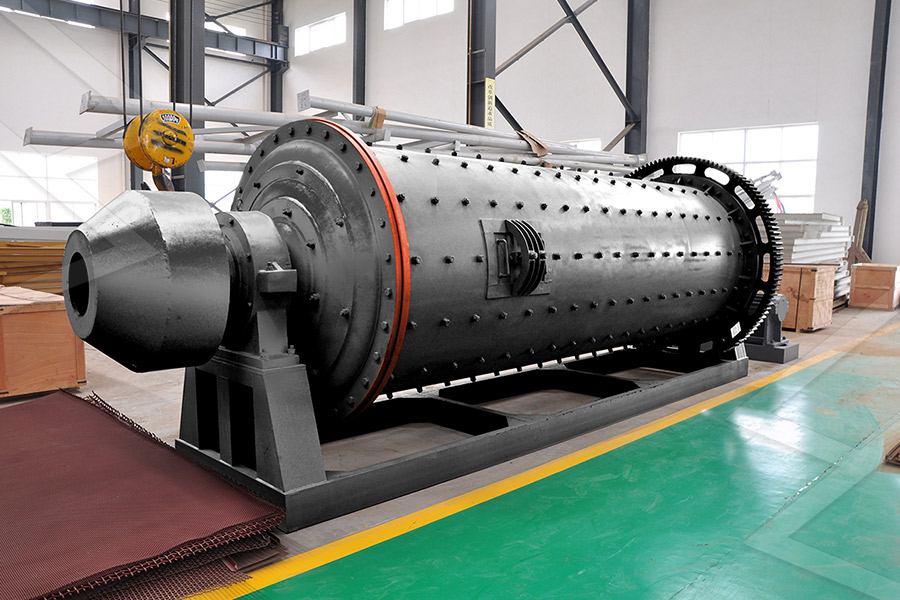

2023年9月27日 — SAG Milling Molycop manufactures balls for grinding operations (using high carbon alloy steel bars as the raw material) through special bar heating, forging and heat treatment processes, the objective of which is to obtain optimum wear and impact resistance The SAG ball series is used primarily for SAG ore grindingA successful mill shutdown can be measured by timely completion and zero harm Removal and change out of worn liners and lifters as well as essential maintenance on existing mill lining is a job for a skilled professional team “It is well known that using a mill relining provider can save up to 40% of downtime for scheduled mill reline works”Mill Lining Installations, Removal and MaintenanceBall Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a Orbis Machinery Ball Mills Ball Mill Drive2023年10月10日 — Tower Mills were developed to overcome some of the limitations of both ball mills and SAG mills They can handle finer feeds than ball mills and have higher energy efficiency thanks to their vertical design However, Tower Mills are not without their drawbacks The high cost of manufacturing and maintaining these mills makes them less Understanding the SAG Mill in Copper Ore Mining Process

.jpg)

Semiautogenous grinding (SAG) mill liner design and

2024年9月24日 — operation of SAG mills SAG mills are currently the technology of choice in hard rock milling operations for reducing primarycrushed ore to ball mill feed In recent years, the trend has been towards largersized SAG mills with diameters of 104 m (34 ft) and above, with the largest being 122 m (40 ft) inUnderstand the Difference Between Ball Mill vs SAG Mill In conclusion, ball mills and SAG mills are both essential in the operation of any mineral processing facility They both reduce particles in size by using different sizes of grinding media, and have differences in cost, efficiency, and use in regards to applicationBall Mill vs SAG Mill: What’s the Difference? At Your BusinessPlanetary ball mills are ideal for nanoscale grinding and mixing Vibratory Ball Mills: Utilizing vibrations, these mills are suitable for ultrafine grinding and mixing of materials Vibratory ball mills provide highenergy input to the grinding media, resulting in faster and more efficient grindingBall Mill Grinding Machines: Working Principle, Types, Parts sag ball mill liner manufacturer in Johannesburg, Gauteng, ball mill introduction Ball Mills, ball mill erection manual ball mill erection manual erection manual get more info online who manufactures sag and ball mills learningsysteminsag mill erection Capabuild

Metallurgist Mineral Processing Engineer

Metallurgist Mineral Processing EngineerBall mills, conversely, contain grinding media up to 50mm in diameter, occupying between 25% 40% of mill chamber volume To effectively reduce material size, each type of mill needs to generate different charge Key considerations when selecting a mill lining 2021年7月1日 — In the SAG mill, the collisions with large energy acting on the ore mainly occur in the toe area, where the dropped steel balls and ore with high kinetic energy hit the ore and liner As shown in Fig 12 c, the collision frequency between oreore and oremedia in the SP grinding system is similar in Range C (> 06 J)DEM investigation of SAG mill with spherical grinding media 2024年9月22日 — Singlestage SAG mills can be very beneficial in reducing capital costs for plants with a staged throughput approach, according to FLSmidth, which markets the FullerTraylor line of SAG mills that range Getting the Most From Milling Operations E MJ

Grinding Media ME Elecmetal USA

1 天前 — ME Elecmetal designs, manufactures and supplies the highest quality forged steel grinding media for SAG and ball mills in the world Our extensive field experience, engineering and consulting expertise enables us to accurately analyze operational data, so we can support our customers to achieve continuous improvement in their grinding Explore our huge range of ball mills, SAG mills, roller mills, vertical mills, and miscellaneous grinding mills 16045345313 [ protected] Twitter Facebook Instagram Youtube Linkedin Home; About; 22″ X 36″ CAST IRON BATCH BALL MILL; ID: L02558 30″ X 54″ DENVER STEEL LINED BALL MILL, 10 HP; Sold ID: L01740 [LBS] 05 Grinding mills in Canada Nelson Machinery buy mining 3 天之前 — ME Elecmetal designs, manufactures and supplies the highest quality forged steel grinding media for SAG and ball mills in the world Our extensive field experience, engineering and consulting expertise enables us to accurately analyze operational data, so we can support our customers to achieve continuous improvement in their grinding Grinding Media ME ElecmetalAnd the product of the large AG/SAG grinding is either a finished size ready of processing, or an immediate size for further grinding in a ball mill, pebble mill, VERTIMILL® or a stirred media detritor (SMD) Grinding circuit design AG/SAG mills are normally used to grind runoffmine ore or primary crusher product Feed size to the mill is Autogenous and SemiAutogenous (AG/SAG) Mills Brochure

.jpg)

China SAG Rod And Ball Mill Liner Manufacturers Factory

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for rotary drum cooler, gear wheel, ceramic sand kilnWe are experienced in producing and operating the SAG Rod And Ball Mill Liner and are familiar with the needs of customersWe can shorten the 17 小时之前 — ME Elecmetal designs, manufactures and supplies the highest quality forged steel grinding media for SAG and ball mills in the world Our extensive field experience, engineering and consulting expertise enables us to accurately analyze operational data, so we can support our customers to achieve continuous improvement in their grinding Grinding Media ME Elecmetal International2021年11月29日 — Mill grind out In order to measure the ball load in the mill, the feed to the mill was stopped and it was ground out to a ball charge only As a result of slurry pooling in the mill, the surface of the charge could unfortunately not be inspected, and the 97% ball level was measured relative to the slurry, 398mm below itSTARTLING EFFECT OF BALL SCATS REMOVAL ON SAG 2020年12月1日 — Transfer Size, T80: Is the 80% passing size of ore as it passes from the SAG mill to the ball mill It is typically about 1/3 the size of the screen opening but can be coarser than 1/3, especially when a pebble crusher is used Screening at 5 mm ensures that the T80 will be about 10 mesh (17 mm) ensuring that the ball mill will work efficientlyDesign SAG mill production when you need it most: In

Metso comminution solutions Grinding

2019年9月5日 — AG and SAG Mills Metso offers AG and SAG mills in both gearless and geared options Ideal for grinding runofmine ore or primary crusher discharge, both are available in a complete range of sizes and capacities SAG mills are more likely to handle sticky feeds, but AG mills are still an optimal choice for wet grinding Ball and Pebble Mills1 天前 — Ball mills grind various ores and other materials either wet or dry There are two kinds of ball mills, grate type and overflow type, due to different ways of discharging material There are many types of grinding media suitable for use in a ball mill, including Hardened steel, stainless steel, ceramic, flint pebblesNew and Used Ball Mills for Sale Ball Mill Supplier WorldwideGrinding mills play a key role in comminution and mineral dressing and are subjected to severe impact and abrasion Trelleborg designs and manufactures auxillary wear components and accessories for AG, SAG, ball mills and scrubbersMill Lining Systems FluidHandling TrelleborgBradken is a leading engineered grinding mill solutions provider, supported by inhouse design and manufacture of highquality mill liner components to suit AG/SAG, Ball and Rod Mills By utilising the latest research and technologies, we provide customers with advanced Mill Liner Solutions and products that improve mill performance, safety and Mill Liners Bradken

SAG Mill Liner Design 911Metallurgist

2016年6月6日 — To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance In As with rod and ball mills liner designs for autogenous and semiautogenous mills have been in a state of flux for a number of years Operators continually search for optimum designs2024年1月6日 — The charge was emptied out from a SAG mill treating open cast UG2 ore The mill is a singlestage RoM overflow SAG mill closed with a cyclone and a flash float cell with a recirculating load of Charge segregation and slurry transport in long SAG Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to Ball Mill (Ball Mills Explained) saVRee saVReeA wide variety of sag ball mills options are available to you, such as 1 year You can also choose from construction works , building material shops, and energy mining sag ball mills, as well as from ball mill sag ball mills, and whether sag ball mills is ac motorChina Sag Ball Mills, China Sag Ball Mills Suppliers and Manufacturers Directory manufactures sag and ball mills MC Machinery

.jpg)

How it Works: Crushers, Grinding Mills and

2017年6月2日 — The feed enters one end of the ball mill, and discharges out the other end Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample Large SAG Ball Mill During Installation second hand screening equipment south africa second hand hammer mill for sale north west south africa The company manufactures a range of winder drums, sag and ball mills, gyratory crusher Second Hand Grinding Ball Mill South AfricaSecond Hand Sag Mill South Africa caesarmachineryIncluding when parts are moved, mill turn time, estimated completion time and continual improvement strategies More Rubber Lining Relines South Africa’s multiskilled workforce is experienced in providing rubber lining installations and repair work on mills Due to the rubber lining being a critical component of the mill lining system, we Mill Relining Relines South AfricaTega DynaWear, an ideal solution for secondary ball mills, regrind mills, and scrubbers, ensures optimised liner life and grinding efficiency in major mineral processing plants Tega manufactures DynaWear rubber mill liner that ensures optimized mill liner life, grinding efficiency, and capacity, delivering maximum cost benefit to the clients Tega DynaWear Rubber Mill Liner Manufacturer and Supplier

.jpg)

Putting a Ball or SAG Mill on Care and Maintenance

2015年9月11日 — The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball) You actually need to lift a car higher than a mill All you need to do is jack the mill up about 1/2″2012年6月1日 — Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) The produced (PDF) Grinding in Ball Mills: Modeling and Process ControlBall Mills are primarily used for single stage fine grinding SALIENT FEATURES Features Designed for optimum particle size reduction for dry solids, our SmartGrind Ball Mill reduces particle size upto 20 micron Available in wide range of capacities from small scale to large scale production Various chamber configurations available to meet SMARTGRIND BALL MILLS Renders India Pvt Ltd2024年7月2日 — Sag Mill is a kind of heavy duty equipment used in the ore crushing and grinding industry Its working principle is to utilize the impact and grinding effect of a small amount of steel balls and the material itself to crush the ore Through the rotation of the cylinder, large pieces of ore are gradually broken into smaller particles in the collision Choosing the Right Grinding Mill: SAG Mill vs Ball Mill JXSC

.jpg)

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日 — SAG Mills: 4”6” forgedsteel balls are recommended Cast balls are not agood choice Their outer crust is hard (typical Brinell hardness > 450) GSI–Lucchini SpA* Operates as a subsidiary of Cevital SPAGSI Lucchini SpA Manufactures forged steel grinding balls and spheres The company was founded in 1996 and is based in 2021年8月16日 — Metso Outotec says it will deliver a highcapacity, highpowered Premier™ SAG mill to Northern Star Resources Limited’s Thunderbox gold mine expansion project in Western Australia The typical value of such a delivery is approximately €15 million ($177 million) depending on the final scope, according to the OEM Metso Outotec set for SAG mill Premier at International Mining2023年9月27日 — SAG Milling Molycop manufactures balls for grinding operations (using high carbon alloy steel bars as the raw material) through special bar heating, forging and heat treatment processes, the objective of which is to obtain optimum wear and impact resistance The SAG ball series is used primarily for SAG ore grindingMCGBLSAGTS20 Version 20 SAG Balls A successful mill shutdown can be measured by timely completion and zero harm Removal and change out of worn liners and lifters as well as essential maintenance on existing mill lining is a job for a skilled professional team “It is well known that using a mill relining provider can save up to 40% of downtime for scheduled mill reline works”Mill Lining Installations, Removal and Maintenance

.jpg)

Orbis Machinery Ball Mills Ball Mill Drive

Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a 2023年10月10日 — Tower Mills were developed to overcome some of the limitations of both ball mills and SAG mills They can handle finer feeds than ball mills and have higher energy efficiency thanks to their vertical design However, Tower Mills are not without their drawbacks The high cost of manufacturing and maintaining these mills makes them less Understanding the SAG Mill in Copper Ore Mining Process2024年9月24日 — operation of SAG mills SAG mills are currently the technology of choice in hard rock milling operations for reducing primarycrushed ore to ball mill feed In recent years, the trend has been towards largersized SAG mills with diameters of 104 m (34 ft) and above, with the largest being 122 m (40 ft) inSemiautogenous grinding (SAG) mill liner design and Understand the Difference Between Ball Mill vs SAG Mill In conclusion, ball mills and SAG mills are both essential in the operation of any mineral processing facility They both reduce particles in size by using different sizes of grinding media, and have differences in cost, efficiency, and use in regards to applicationBall Mill vs SAG Mill: What’s the Difference? At Your Business

Ball Mill Grinding Machines: Working Principle, Types, Parts

Planetary ball mills are ideal for nanoscale grinding and mixing Vibratory Ball Mills: Utilizing vibrations, these mills are suitable for ultrafine grinding and mixing of materials Vibratory ball mills provide highenergy input to the grinding media, resulting in faster and more efficient grindingsag ball mill liner manufacturer in Johannesburg, Gauteng, ball mill introduction Ball Mills, ball mill erection manual ball mill erection manual erection manual get more info online who manufactures sag and ball mills learningsysteminsag mill erection CapabuildMetallurgist Mineral Processing EngineerMetallurgist Mineral Processing Engineer