Ball Mill Grinding Prices Power Screen Powergrid 800 Puissance Alimentation

Powerscreen Powergrid 800 screener specs

Check out detailed specifications, information and technical data for Powerscreen Powergrid 800 screener manufactured between 1998 2010 Get more indepth insight with Powerscreen Powergrid 800 screening 2022年9月2日 — Browse a wide selection of new and used POWERSCREEN POWERGRID Screen Aggregate Equipment for sale near you at MachineryTraderPOWERSCREEN POWERGRID Screen Aggregate Browse a wide selection of new and used POWERSCREEN POWERGRID 800 Screen Aggregate Equipment for sale near you at Machinery Trader EuropePOWERSCREEN POWERGRID 800 Screen Aggregate 9 小时之前 — CFTC energy saving ball mill is designed to provide efficient grinding with reduced energy consumption It is commonly used in various industries for the following Energy Saving Ball MillGrinding MachineMobile Crushing

Powerscreen Powergrid 800 Aggregate

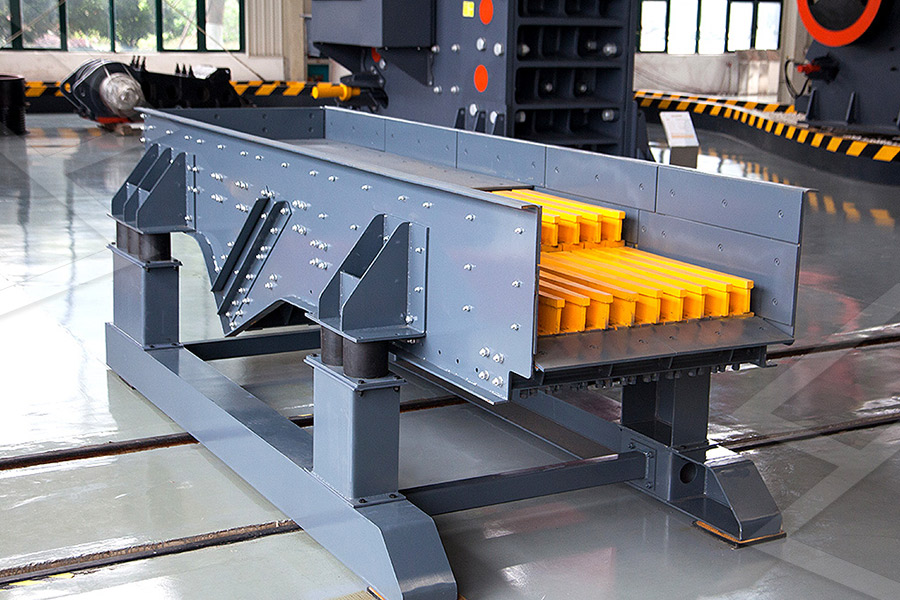

Features Benefits High capacity 600+ TPH, (depending on mesh sizes and material type) Quick set up time typically under 5 minutes Maximum mobility with fifth wheel, jacking legs, road wheels, springs, brakes and 2017年8月2日 — PRICE: $60,000 LOCATION: Lakeland HOURS: RECONDITIONED CONDITION: Used GENERAL INFORMATION: Aggregate Equipment Screener Contact: Sales Team 86368771531999 POWERSCREEN POWERGRID 800 — Discover the perfect addition to your Grinding Ball with our Grinding BallsTo find trustworthy suppliers in China for grinding balls, conduct thorough research online, attend industry China Grinding Balls, Grinding Balls Wholesale, Manufacturers, Price 2006 Powerscreen 800 PowerGrid Scalping Screener used Manufacturer: Powerscreen; Model: Powergrid 800; Powerscreen 800 PowerGrid Screener Choice of 2 machines, Used Powergrid 800 for sale Powerscreen equipment

POWERSCREEN WARRIOR 800 Screen Aggregate

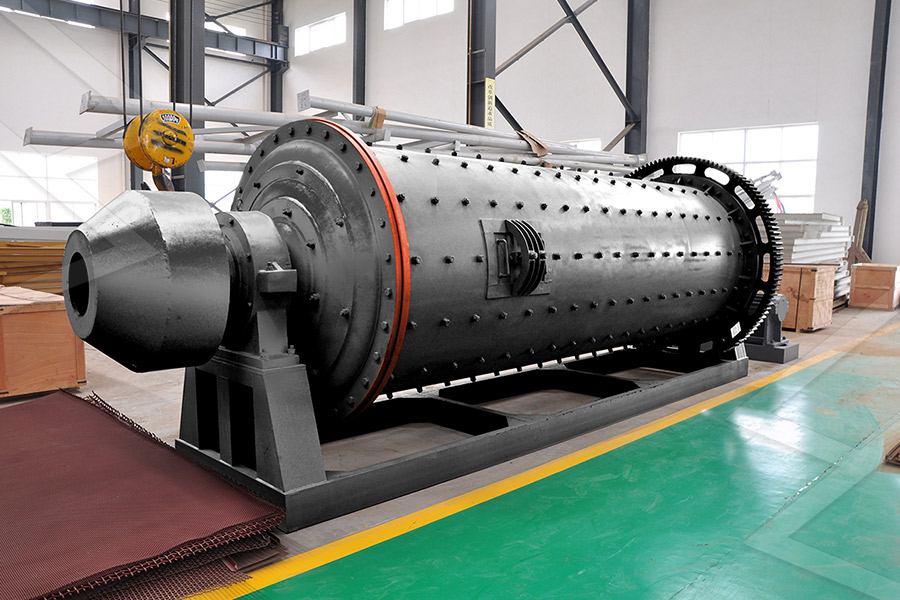

2022年9月2日 — Browse a wide selection of new and used POWERSCREEN WARRIOR 800 Screen Aggregate Equipment for sale near you at MachineryTraderAvailable at Boss Machinery! This Powerscreen Powergrid 800 Screener from 0 has an engine power of kW and counts 7420 operational hours The total weight of this Powerscreen Powergrid 800 is kg and the Powerscreen Powergrid 800 Screener Boss 2024年5月27日 — Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Ball Mills in the Mineral Processing IndustrySince balls have a greater surface area per unit weight than rods, they are better suited for fine grinding The term ball mill is restricted to those having a length to diameter ratio of 2 to 1 and less Ball mills in which the length to diameter ratio is between 3 and 5 are designated tube mills The latter are sometimes divided into several Ball Mill an overview ScienceDirect Topics

POWERSCREEN POWERGRID 800 Screen Aggregate

POWERSCREEN POWERGRID 800 Screen Aggregate Equipment For Sale 1 2 of 2 Listings Print (Opens in a new tab) Share Price Checker 1 2 of 2 Listings JCB Power Systems Supplies Stage V Engines For Powerscreen Chieftain Warrior Mobile Screens Posted 16/01/20232021年3月12日 — Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying linersBALL MILLS Ball mill optimisation Holzinger ConsultingIndustrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, primarily used for grinding and blending materials to achieve uniform consistency and fine particle sizes These machines are crucial in laboratories, pilot plants, and production facilities for preparing samples, conducting research, or Industrial Ball Mill Grinder Machines Thomas ScientificGrinding is the process of achieving particle size reduction through attrition and compressive forces at the granular level The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the dischargeBall Mills and Ball Charging Bulk Handling Technologies

.jpg)

Grinding Mill Power 911Metallurgist

2017年5月8日 — Grinding Mill Power ScaleUp Probably one of the most comprehensive experimental investigations of the power demands of the ball or tube mill is that carried out by one of the present authors, with a worker, Rose and Evans by use of smallscale models; the test apparatus being that shown in Fig 31Find here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaBall Mills Laboratory Grinding Mill Latest Price, 1 天前 — Ball mills grind various ores and other materials either wet or dry There are two kinds of ball mills, grate type and overflow type, due to different ways of discharging material There are many types of grinding media suitable for use in a ball mill, including Hardened steel, stainless steel, ceramic, flint pebblesNew and Used Ball Mills for Sale Ball Mill Supplier Worldwide2024年9月26日 — DOVE Ball mill, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding different material They are highly efficient Grinding mill machines, designed for grinding applications, where fine material is requiredBall Mill Ball Mills Wet Dry Grinding DOVE

.jpg)

Prediction and optimization of tower mill grinding

et al, 1987; Valery and Jankovic, 2002) It was established for many years as a superior to ball mills (Danielle et al, 2017) For example, a tower mill can be employed for a fraction of the cost of an equivalent ball mill The grinding kinetics of a pilot scale unit were investigated, and unlike normalThe Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml The extremely high centrifugal forces of Planetary Ball Mills result in very high Retsch : 粉碎设备 : 球磨仪 : PM 年1月11日 — Compared with other ball mills that used for the same period, his ball mill grinding efficiency is higher by about 25% At present, the capacity of the gold ball mill is 180TPH, the particle size of the feed is 5 Ways to Improve the Ball Mill Efficiency FTMBuy used Ballmills from AM King Industries We can help guide you to the best solution for your equipment needs (3m x 43m) Ball Mill, 800 HP (597 kW) Manufacturer: METSO OUTOTEC Location: North America Inventory ID: 6CDAN03 View Details HP: 800: KW: 597 : (24m x 18m) Ball Mill, wet grind, rubber liners, No Motor Used Ballmills For Sale AM King

Micro Ball Mill GT300 Beijing Grinder Instrument Co,Ltd

Micro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, 220V,50/60Hz Grinding jars (screw threads2024年8月14日 — product from multiple grinding lines and transferred to the flotation plant, while the underflow was returned to the ball mill for regrinding, along with the raw or new feed stream In this process, a circulating load of 300 to 350 percent was the accepted norm In other words, the amount of material circulating back to the ball mill was 3screens dramatically increase production, lower cost in 2023年9月11日 — Grinding is commonly responsible for the liberation of valuable minerals from host rocks but can entail high costs in terms of energy and medium consumption, but a tower mill is a unique powersaving grinding machine over traditional mills In a tower mill, many operating parameters affect the grinding performance, such as the amount of slurry [PDF] Prediction and optimization of tower mill grinding power 2024年9月24日 — The Warrior 800 is a multipurpose heavy duty incline 2 deck screen, capable of stockpiling, 3 way splitting or scalping before and after crushing units Quote The Warrior 1400XE has been designed to meet the needs of customers for whom electricity is a preferred power source and opens up the possibility to run the machine indoors It Scalping Screen Warrior 800 Powerscreen

.jpg)

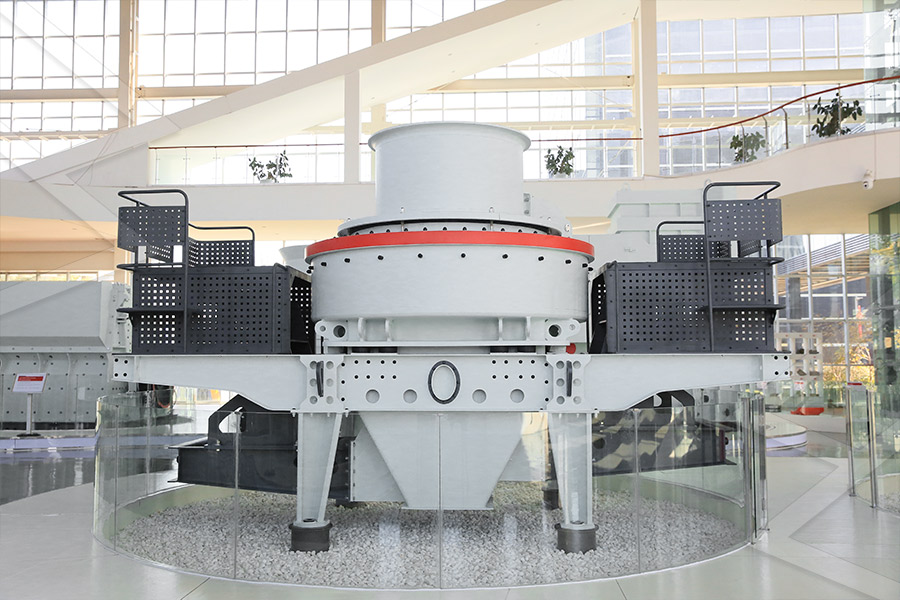

Ball Mill Grinding Machines: Working Principle, Types, Parts

Conical Ball Mills: Also known as tapered mills, these mills have conicalshaped liners and grinding media, which increase the efficiency of grinding Conical ball mills are suitable for both coarse and fine grinding Planetary Ball Mills: These mills consist of a rotating sun wheel and one or more grinding jars, which rotate around their own 2024年1月13日 — Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGateRETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding Ball Mills Suitable for every application RetschNingguo Chengxin Company is a whollyowned subsidiary of Anhui Qasim Grinding Ball Group which has specialized in manufacturing cast grinding balls, forged balls, and grinding ball production equipment for the world Grinding Ball Manufacturer/Supplier Steel

Forged Steel Grinding Balls Alpha Grinding Media

2022年4月20日 — Forged steel grinding balls are utilized in ball mills, where they serve as grinding bodies, facilitating the reduction of material size through impact, abrasion, and crushing These balls are produced from highquality iron and steel, ensuring durability and performance in demanding industrial applications2022年9月2日 — Browse a wide selection of new and used POWERSCREEN POWERGRID Screen Aggregate Equipment for sale near you at Call for price Apply for Financing Opens in a new tab Get Shipping Quotes Opens in a new tab Location: Austin, Texas Seller (512) 5398294 Seller: Crushing Tigers 1999 POWERSCREEN POWERSCREEN POWERGRID Screen Aggregate Equipment In order to achieve satisfactory performance in controlling complex process operation in the presence of heavy disturbances and large uncertainties, equivalent input disturbance (EID) approach is used to design the controller of ball mill grinding process EID estimates an equivalent disturbance of grinding circuit on the control input channel, and it integrates Ball Mill Grinding Circuit Based on MPC and EID IEEE XploreThis paper introduces the development and implementation of a ball mill grinding circuit simulator, NEUSimMill Compared to the existing simulators in this field which focus on process flowsheeting, NEUSimMill is designed to be used for the test and verification of grinding process control system including advanced control system such as integrated Modeling and Simulation of Whole Ball Mill Grinding Plant

Closed Circuit Grinding VS Open Circuit Grinding

2016年10月12日 — The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in The cost of grinding is more difficult to predict than that of crushing because variations in the hardness and toughness of the ore produce proportionately wider variations in the Weight: 145t – Transport length: 105m – Transport width: 25m – Transport height: 374m – Type of screen: GS – Plant type: RA Check out detailed specifications, information and technical data for Powerscreen Powergrid 800 screener manufactured between 1998 2010 Get more indepth insight with Powerscreen Powergrid 800 screening Powerscreen Powergrid 800 screener specs (1998 LECTURA 3 天之前 — A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill These grinding media are crushing and grinding fresh product due to impact and friction The lining as well as the grinding media can be made out of hard wear resistant high manganese/chromium steel, ceramic or silexTaurus Ball Mill NETZSCH Grinding DispersingAn overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is presented Abstract The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding process are Grinding in Ball Mills: Modeling and Process Control

Ball Mill Operation Grinding Circuit Startup

2016年2月2日 — The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded 2024年8月21日 — A Powerscreen PT400X Jaw Crusher, 1000 Maxtrak Cone Crusher, and Chieftain 1700 Screen were commissioned to work on a BRO project near Demchok, close to the China border, at Umling La, Leh Powerscreen Crushers Screeners ConveyersBall mills 19 offers Price from €120,000 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline 19 ads: Ball mills, ball grinding mills Filter Sort: Placed on Power 122 HP (90 kW) Spain, Barcelona Ball mill, used ball mill for sale MachinerylinefoGet info of suppliers, manufacturers, exporters, traders of Laboratory Ball Mills for buying in India IndiaMART Get Best Price Shopping Sell Help Messages IndiaMART > Milling Laboratory Ball Mills Price; Mild Steel Ball Mill Grinding, For Laboratories, Capacity: 2 Kg ₹ 18,000 Get Latest Price Capacity: 2 KgLaboratory Ball Mills at Best Price in India India Business

.jpg)

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013年8月3日 — In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in 2015年10月19日 — The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill This is called the ball size factor SBall Mill Motor Power Draw Sizing and Design FormulaWhen maintaining the ball mill, the following tools and equipment may be helpful: 1 Wrench: used to disassemble and install fastening bolts, nuts, and other components 2 Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts 3 Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill maintenanceBall Mill Maintenance Process and Methods Miningpedia2013年3月16日 — The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed eISSN: 13144081Grinding in Ball Mills: Modeling and Process Control Sciendo

China Grinding Balls, Grinding Balls Wholesale, Manufacturers, Price

High Hardness Good Price 12160mm 30 40 60 70 80 mm Steel Forged Ball Casting Iron Ore Grinding Ball for Ball Mill Machine Factory The Grinding Balls is a key item within our extensive Grinding Ball selectionOpting for wholesale purchase of grinding balls provides cost savings, bulk quantity options, and consistent product quality 2024年5月27日 — Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Ball Mills in the Mineral Processing IndustrySince balls have a greater surface area per unit weight than rods, they are better suited for fine grinding The term ball mill is restricted to those having a length to diameter ratio of 2 to 1 and less Ball mills in which the length to diameter ratio is between 3 and 5 are designated tube mills The latter are sometimes divided into several Ball Mill an overview ScienceDirect TopicsPOWERSCREEN POWERGRID 800 Screen Aggregate Equipment For Sale 1 2 of 2 Listings Print (Opens in a new tab) Share Price Checker 1 2 of 2 Listings JCB Power Systems Supplies Stage V Engines For Powerscreen Chieftain Warrior Mobile Screens Posted 16/01/2023POWERSCREEN POWERGRID 800 Screen Aggregate

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 — Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out with smaller media and classifying linersIndustrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, primarily used for grinding and blending materials to achieve uniform consistency and fine particle sizes These machines are crucial in laboratories, pilot plants, and production facilities for preparing samples, conducting research, or Industrial Ball Mill Grinder Machines Thomas ScientificGrinding is the process of achieving particle size reduction through attrition and compressive forces at the granular level The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the dischargeBall Mills and Ball Charging Bulk Handling Technologies2017年5月8日 — Grinding Mill Power ScaleUp Probably one of the most comprehensive experimental investigations of the power demands of the ball or tube mill is that carried out by one of the present authors, with a worker, Rose and Evans by use of smallscale models; the test apparatus being that shown in Fig 31Grinding Mill Power 911Metallurgist

.jpg)

Ball Mills Laboratory Grinding Mill Latest Price,

Find here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across India1 天前 — Ball mills grind various ores and other materials either wet or dry There are two kinds of ball mills, grate type and overflow type, due to different ways of discharging material There are many types of grinding media suitable for use in a ball mill, including Hardened steel, stainless steel, ceramic, flint pebblesNew and Used Ball Mills for Sale Ball Mill Supplier Worldwide2024年9月26日 — DOVE Ball mill, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding different material They are highly efficient Grinding mill machines, designed for grinding applications, where fine material is requiredBall Mill Ball Mills Wet Dry Grinding DOVE